Our Activity Fields:

It is a construction enterprise specialized in the design and installation of various classes of clean room. We have leading advantage on clean-room design and engineering, and rich experience on international project management. We provide professional clean room design & construction for applications in electronics, pharmaceutical (GMP), agribusiness, food, automotive, Biological industries. We are also capable for mechanical and electrical installation works for manufacturing plants, hotel and apartments (including processing pipe, electricity, and intellective control system etc). We have strong capabilities for clean room design and construction from class 100 to class 300,000, mechanical and electrical installation, intellective control system set up, special process piping, especially large facility construction. We have a strong design and construction team, and won a lot of customer recognitions for meeting the tight schedule, ambitious cost target and strict site safety guidelines.

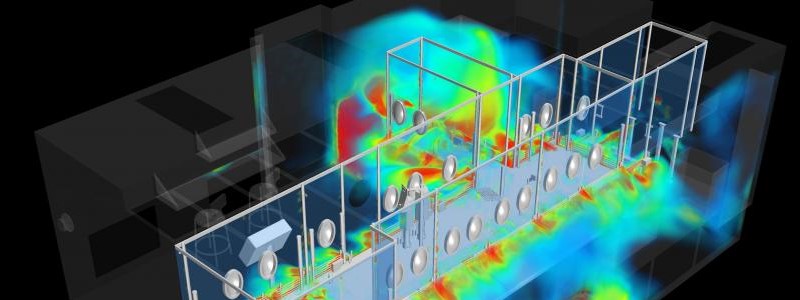

Cleanroom Conceptual Design

In Clean Rooms, to begin a project for the future, with the assurance that the end is going to be a suitable one, it is necessary to start from a Conceptual Design in which a developing process, its requirements and needs are defined.

Cleanroom Basic and Detail Design

The Basic and Detailed engineering is done from the Conceptual Design, defining all the constructive aspects of the project, its facilities and equipment.

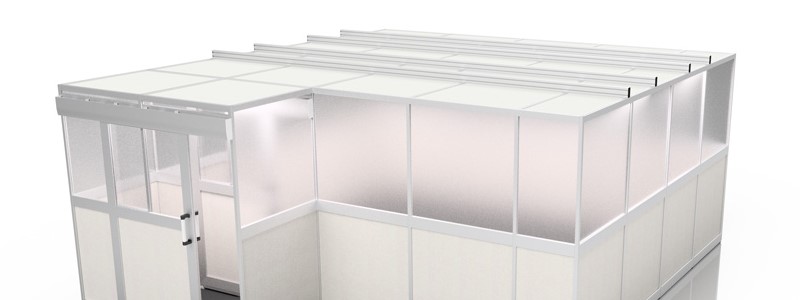

Cleanroom Structure

Covering sandwich ceiling panels and wall panels, cleanroom doors and windows, coving, corner piece and connection accessories, etc.

HVAC System

Covering AHUs, chillers, water piping, air ducting, piping insulation, air and water valves, air filters, air inlets and outlets etc.

Auto-control System

Intercom system, monitoring system, sensors and actuators for temperature , humidity, air flow, cleanliness, noise, controllers, motorized valves, etc.

Cleanroom Floor

Epoxy Floor, PVC Floor and High-rise Floor To be more efficient and effective, we strongly recommend project owner to make the following items ready before cleanroom construction.

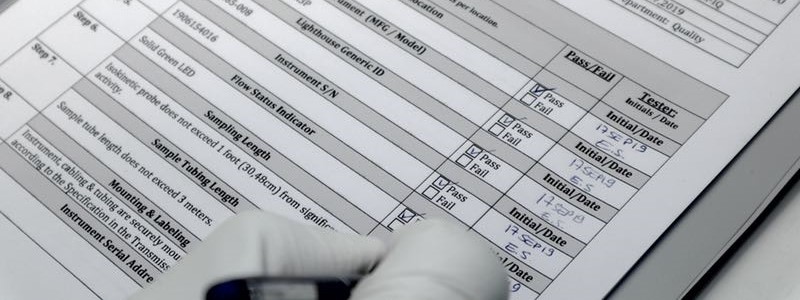

Cleanroom Commissioning

Commissioning is a systematic process of assuring that a building performs in accordance with the design intent and the owner’s operational needs.

Cleanroom Validation

After cleanroom commissioning, we should validate the cleanroom system, and we must ensure the design of the facility is fit for its intended purpose.

Cleanroom Documentation

Validation Documentation consists of Design Qualification Installation Qualification Operation Qualification Performance Qualification